Ultrasonic/laser beam welding

Ultrasonic welding and laser welding are efficient welding techniques for connecting products and materials. Ultrasonic welding is an environmentally friendly technique that requires little maintenance and has short welding times, while laser welding ensures a consistently high quality of the weld seam without the use of filler material. Van Wees Waalwijk specializes in designing custom-made machines using these welding techniques.

ULTRASONIC WELDING TECHNIQUE

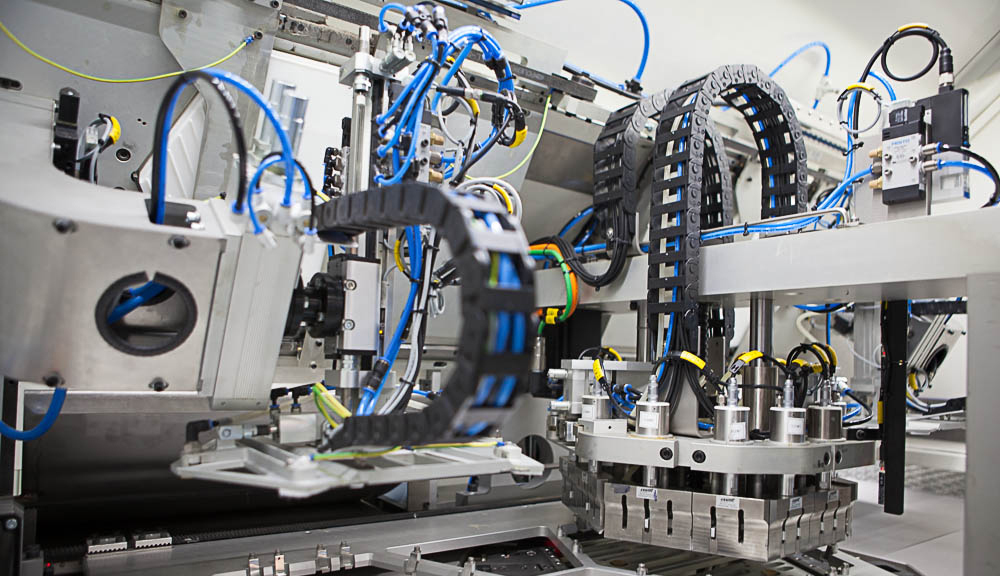

The ultrasonic welding technique is increasingly used as a joining technique. Ultrasonic welding is a cheap welding technique that can be used for various products and materials. The welding times are less than a second and in addition, the ultrasonic welding technique requires little maintenance and is environmentally friendly. Van Wees Waalwijk has proven to be a specialist in the field of customised machines for which ultrasonic welding is used.

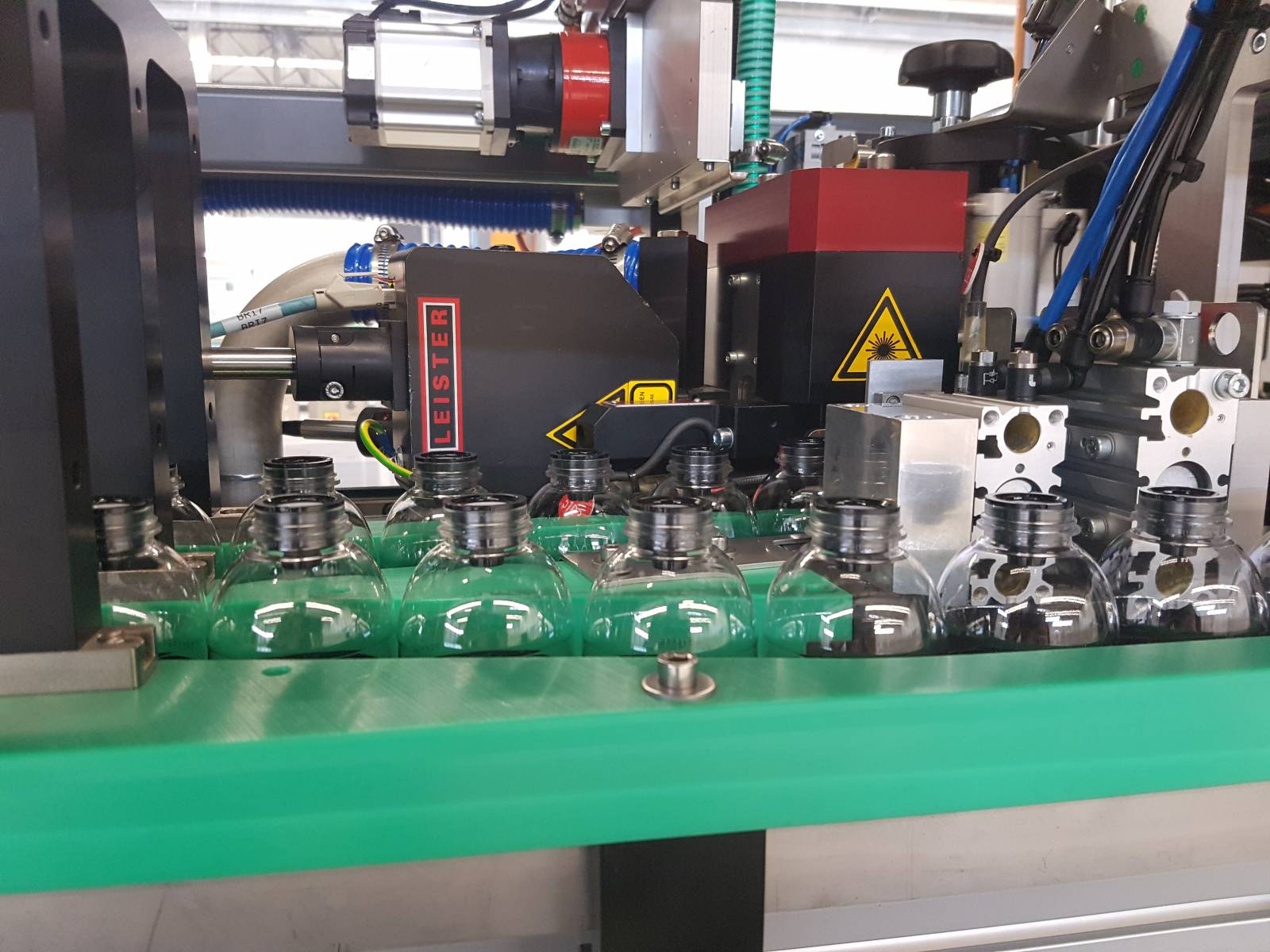

LASER BEAM WELDING WITH A TAILOR-MADE MACHINE FROM VAN WEES WAALWIJK

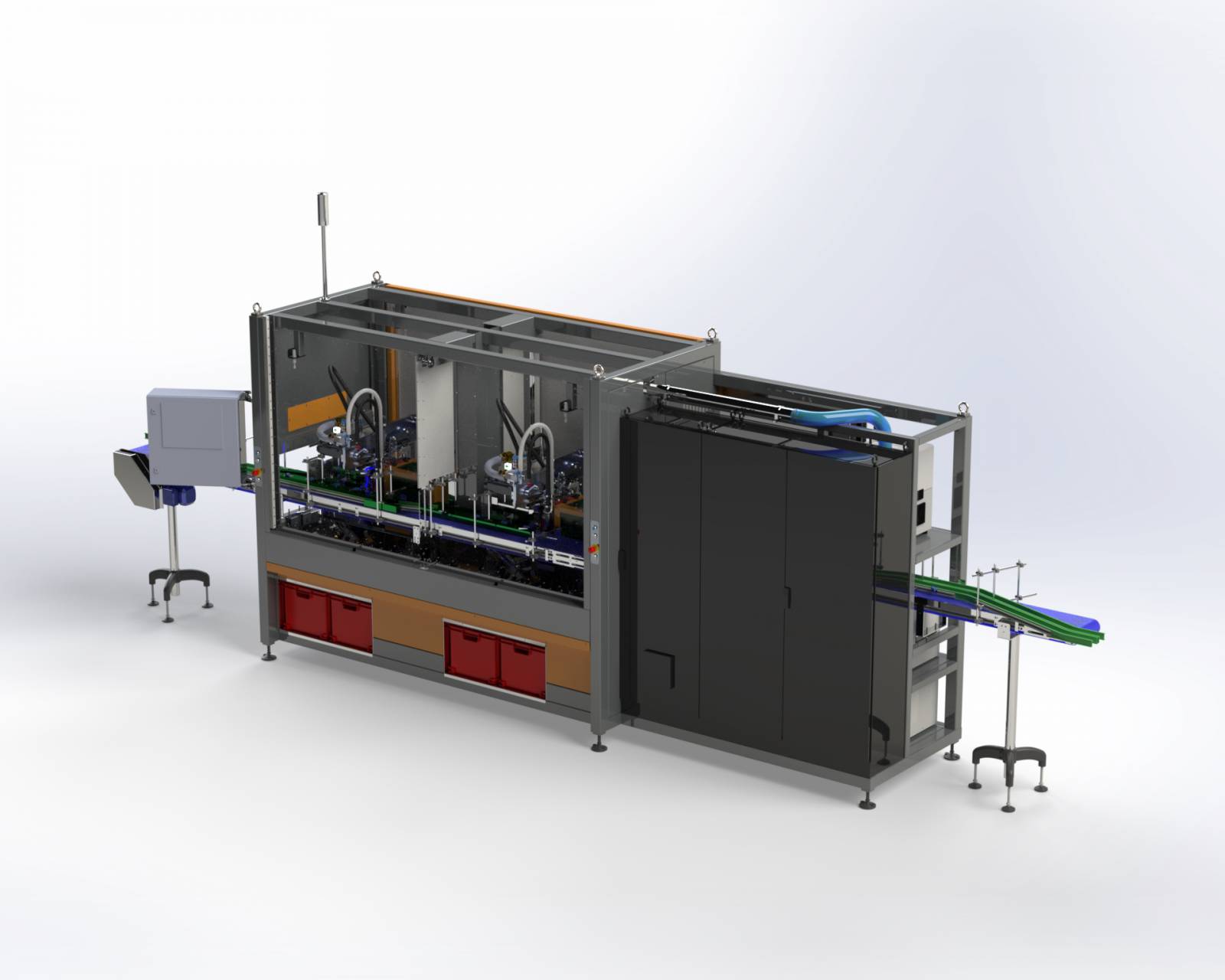

Van Wees Waalwijk specialises in the design and construction of customised machines. Our final products vary from simple sheeting to fully automatic machines, for example for laser beam welding and ultrasonic welding. Our customised machines are turnkey solutions. Van Wees Waalwijk can also look after maintenance, repair and overhaul.

LASER BEAM WELDING OFFERS COMPANIES UNPRECEDENTED OPPORTUNITIES

Laser beam welding offers companies a great number of advantages; it is very suitable for automation for instance. Laser beam welding is a fast welding technique with a low heat input. This technique causes little deformation so even thin sheet material can be welded. Laser beam welding can also be used for non-metallic materials such as plastics.

LASER BEAM WELDING MACHINE MADE BY VAN WEES WAALWIJK

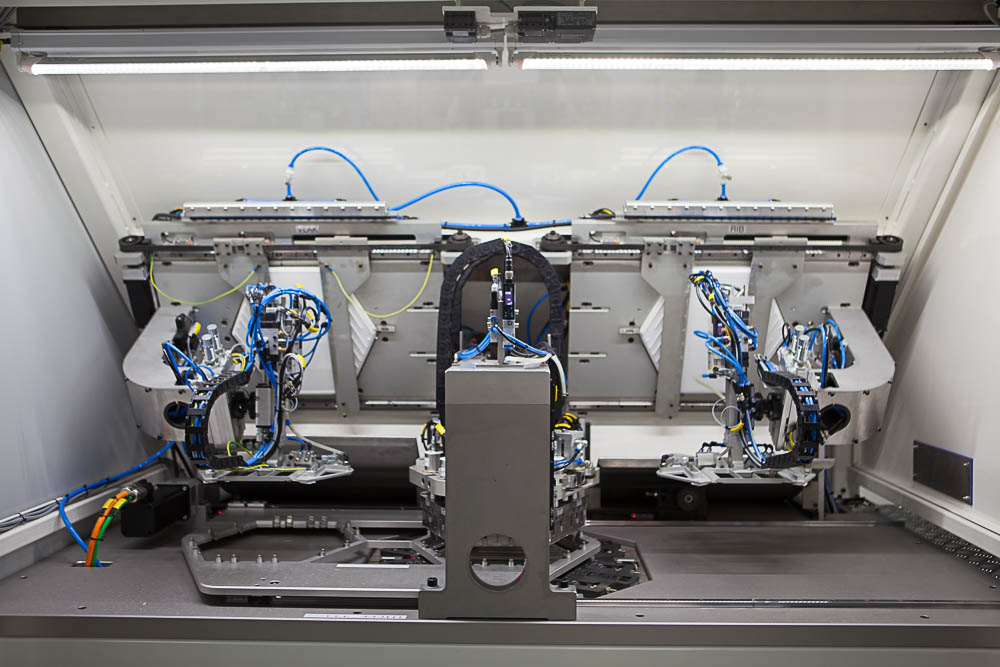

Van Wees Waalwijk provides companies with innovative, customised machines to be able to realise unprecedented production possibilities such as joining plastic parts by means of laser beam welding. A unique laser beam welding machine has been developed for a manufacturer of plastic spray cans based in Waalwijk. Thanks to this technique, plastic parts can be joined and then assembled into a spray can.

Realised projects

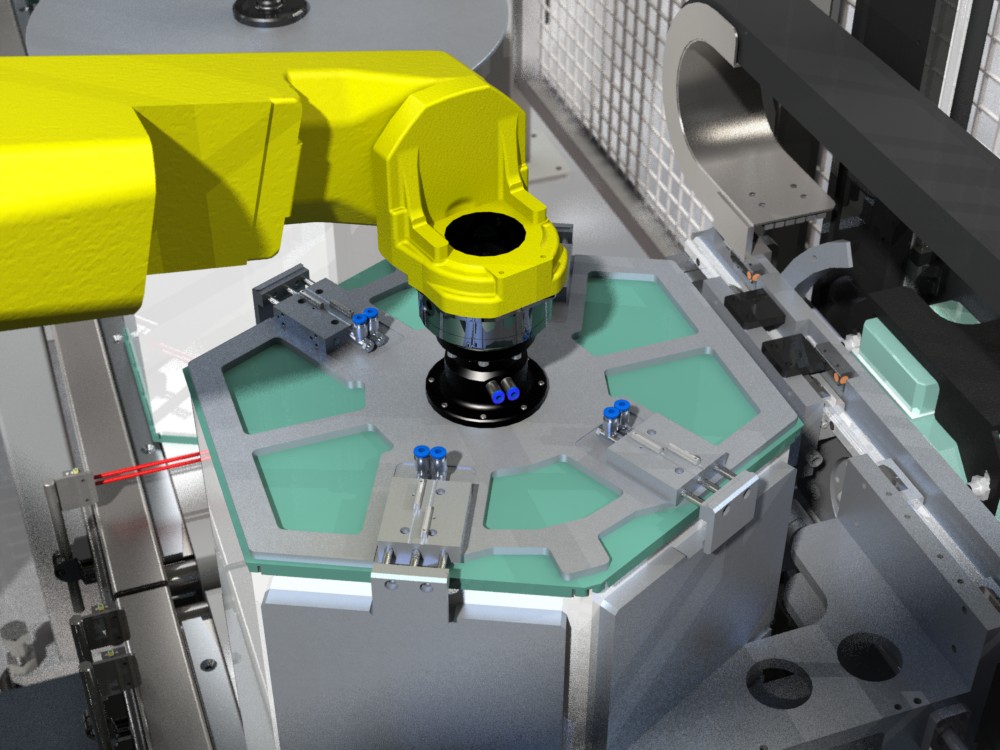

Recair-core: ASSEMBLY MACHINE HEAT EXCHANGER

A heat exchanger, consisting of two types of plastic sheets, is assembled by means of this machine. The sheets are sorted out of different depots and the ultrasonic welding technique is used to weld the sheets together to form one unit.

Contact

Contact information